Real-Time Production Management System

Track, manage, and optimize production performance with real-time data collection via RFID technology.

What is the System?

Our system enables manufacturers to monitor production efficiency in real-time. It leverages RFID technology to automatically collect data from production lines, providing insights into performance, productivity, and bottlenecks.

With seamless RFID integration, you can receive live updates about each unit's progress, efficiency, and operational status. This allows for immediate adjustments, better resource allocation, and improved overall production performance.

Key Features

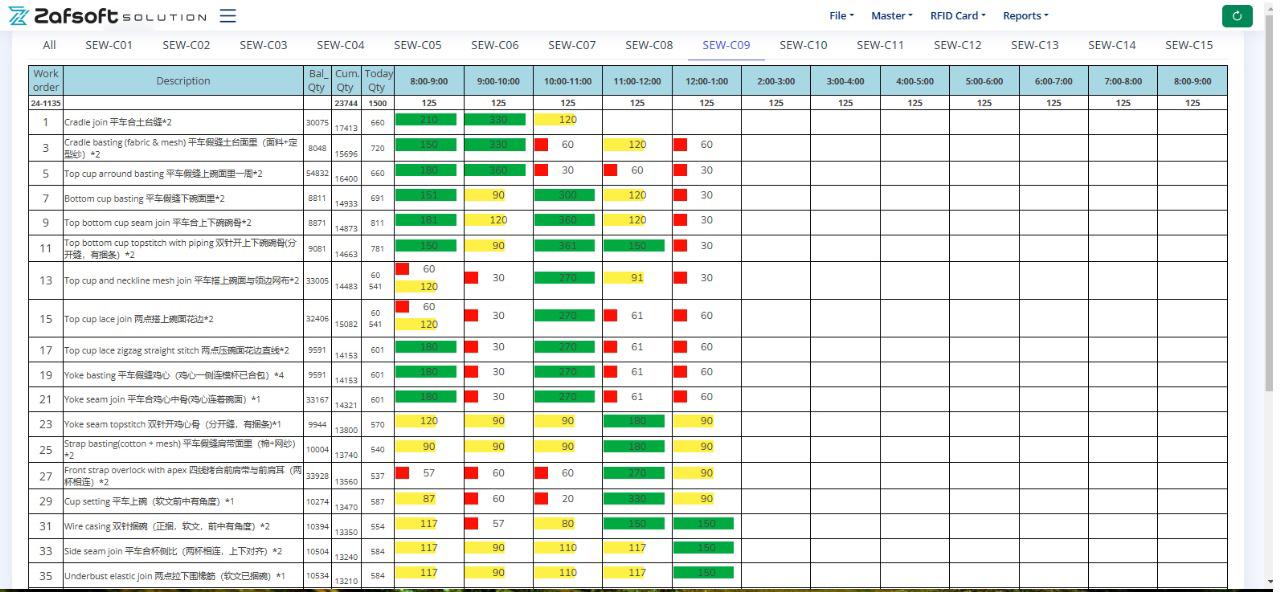

- Real-Time Data: Continuous data collection and monitoring from each production line.

- RFID Integration: Automatic data synchronization from RFID-enabled devices on production units.

- Performance Tracking: Visual insights into production efficiency and trends.

- Alert System: Automated alerts for production status changes, such as slowdowns or stoppages.

Benefits

The Real-Time Production Management System enhances operational efficiency, reduces downtime, and improves overall production output. By utilizing RFID technology, the system eliminates manual data entry errors and provides accurate, up-to-the-minute production data.

Key Benefits:

- Improved decision-making through real-time production insights.

- Higher operational efficiency and reduced manual labor.

- Instant identification of production issues and bottlenecks.

- Enhanced visibility into production data across all lines.

Production Performance Dashboard

Track the overall performance of your production lines through visually appealing charts that show efficiency trends and production statistics in real-time.